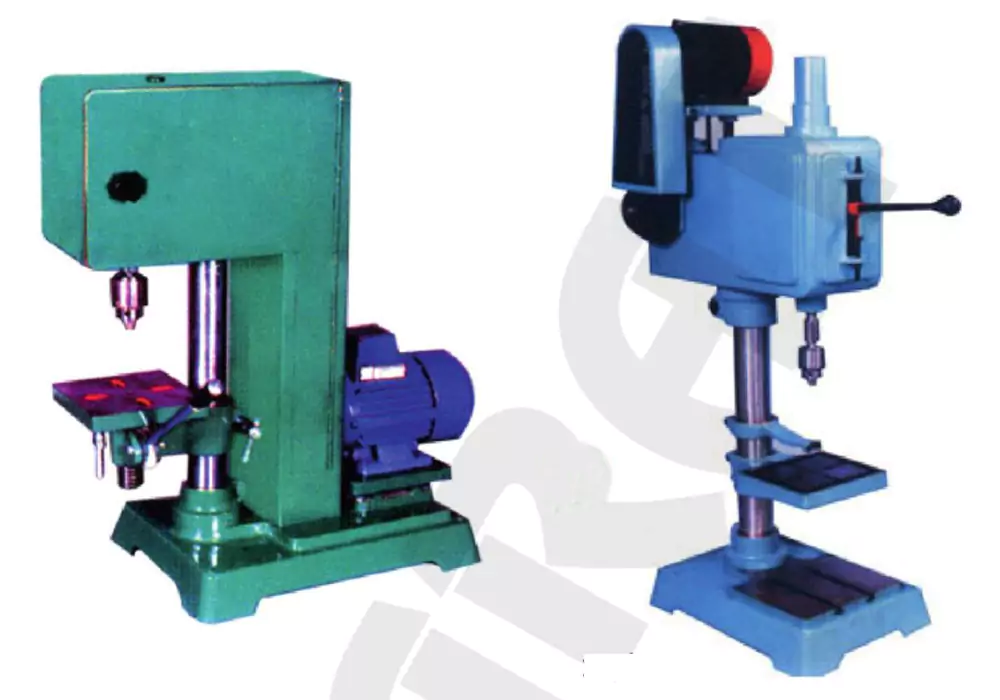

A tapping machine is a machine used for making screw threads by cutting a thread on the workpiece with a tool bit. The cutting tool is called a tap. The tap is held in a tap holder which is mounted in the spindle of the tapping machine. The workpiece is rotated by the spindle and the tap is fed into the workpiece by the tap holder. The tap cuts a thread on the workpiece as it is fed into the workpiece. The tap is then withdrawn from the workpiece and the workpiece is removed from the spindle. The tapping machine is a versatile machine that can be used to create a variety of different screw threads. The machine is easy to operate and can be used to create a variety of different sized threads. The tapping machine is an essential piece of equipment for any manufacturing facility.

We are engaged in supplying a broad range of semi automated tapping machine, which is well acknowledged for its accurate working and efficiency, with the assistance of an expert staff. These machines are obtained from reputable manufacturers that employ high-quality raw materials and cutting-edge technology to ensure complete customer satisfaction. Furthermore, our products are reasonably priced for our valued customers.

Working of tapping machine

Tapping machines are used to create threads in a workpiece. This is done by using a tool called a tap to cut a series of threads into the workpiece. Tapping machines can be used to create threads in a variety of materials, including metals, plastics, and wood. There are many factors to consider when choosing a tapping machine. These include the type of materials you will be tapping, the size of the workpieces, and the speed at which you need to be able to tap. Doing your research ahead of time will help you make the best decision for your needs.

Use of tapping machine?

A tapping machine is a machine used for tapping holes in various materials. There are many different types of tapping machines, each designed for a specific application. The most common type is the hand-held tapping machine, which is used to tap small holes in materials such as wood and plastic. Other types of tapping machines include floor-mounted tapping machines, which are used to tap large holes in materials such as metal, and CNC tapping machines, which are used to tap holes in materials such as aluminium and stainless steel.

Technical Specification

| Specification of Machine | Tapping Machine 6mm. |

Tapping Machine 12mm. |

Tapping Machine 22/25mm.manual |

|---|---|---|---|

| Tapping Machine Capacity | 6mm | 12mm | 22/25mm |

| Drilling Capacity | 3mm | 8mm | 16/19mm |

| Spindle Travel/Table travel (6mm) | 60mm | 75mm | 75mm |

| Distance Spindle to Column | 80mm | 140mm | 237mm |

| Distance between chuck to base | 190mm | 450mm | 670mm |

| Distance between chuck to Work table | Movable | 380mm | 520mm |

| Size of base Plate-L X B | 370 x 250 mm | 480 x 350 mm | 550 x 410 mm |

| Size of Work Table-L X B | 150 x 150 mm | 190 x 220 mm | 260 x 260 mm |

| Diameter of column | 47mm | 74mm | 74mm |

| V-Belt (Inside) | - | inside A-71 | inside B-72 |

| V-Belt for Motor (Outside) | A-36 | A-32 | B-33 |

| No. of Spindle Speeds | 3 | 3 | 3 |

| Forwards Speed Range | 480/750/1400 | 350/620/1100 | 220/320/460 |

| Raverse Speed Range | 480/750/1401 | 420/745/1315 | 260/380/545 |

| Motor Single phase or three phase | 0.5 H.P. , 1440 R.P.M | 1 H.-P. ,1440 R.P.M. | 1.5/2 H.-P. ,1440 R.P.M. |