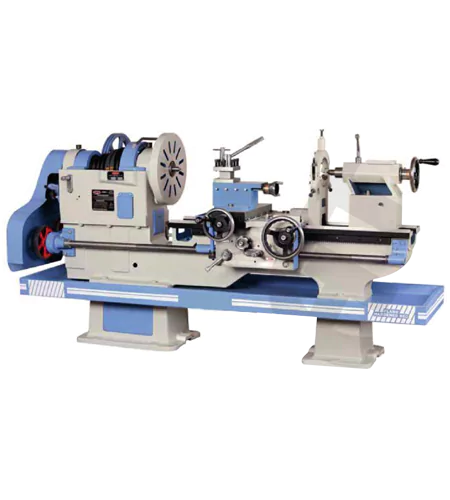

High Quality Heavy-Duty Lathe Machines

A heavy duty lathe machine is used in metalworking operations to perform tasks such as turning, facing, drilling, boring, and thread cutting. These machines are designed for high precision, various specifications, and are often used in industries such as aerospace, automotive, engineering and construction for large-scale and critical components. We offer heavy duty lathe machine with durable quality and long lasting materials. With its precision tooling, adjustable speed control and powerful motor, you get complete control for precision engineering and crafting. Our heavy duty lathe machine is perfect for drilling, turning, cutting and more, it’s easy to set up and use.

A heavy-duty lathe machine is a type of metalworking lathe designed to handle large and heavy workpieces. Heavy-duty lathes typically have a larger spindle bore, longer bed length, and stronger construction compared to standard lathes. They are also equipped with heavier motors and drives, and more robust tooling systems to handle the increased stress and forces generated during heavy machining operations.

Bharat Machinery & Spares (India) are reliable suppliers and exporters, offers a premium quality Heavy Duty Lathe Machine at an unbeatable price. The machine is constructed with durable material, stronger and sturdier than ever before for increased strength and durability in even the toughest of jobs. It has a high capacity for swift operation which makes it great for professional machining applications such as cutting, facing & turning operations across various industries.

Some of the key features of a heavy-duty lathe machine include:

- The main bed being the foundation of lathe is carefully designed and is of high cast grade iron, it has cross ribs to suport its wall and three inverted ‘vees’ assembled with a romovable gap for larger swing.

- The main spindle is of alloy steel and ground to give accurate results.

- The tool is made of out of solid steel block.

- The ‘v’ guideways running on the bed and the slides are most accurately with the bed and the headstock.

Standard Accessories :-

- "Face Plate

- "Chuck Plate

- "Change Gear Set

- "Spindle Sleeve

- "Dead Center(2 Nos.)

- "Tool Past Key

- "Motor Pulley

- "SteadyRest

Speciality :-

- "HardenBed (391 BHN)

- "Tailstock Spindle Harden

- "SKF or Timken make Bearing

- "Border Tray

- "Accuracy as per IS Standard

Extra Accessories :-

- "Follow Rest

- "Water Guard

- "Dog & Trua Chuck

- "Electric Motor

- "Coolant Pump, Tank

- "Nortan Gear Box

- "TapperTurning Attachment

- "Rear Tool-Post

Optional :-

- "Spindle bore 80 or 105

- "Bush or Tapper Roller Bearing

- "Flat Belt or "V" Belt

- "Center Height 12"